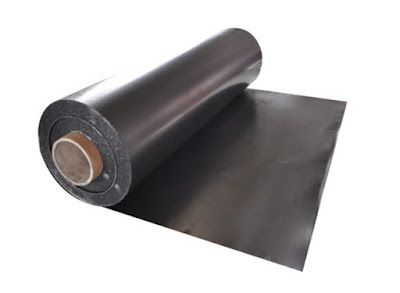

We offer you non-asbestos sheet gasketing

The sheet gasketing technique is designed to outperform a primitive style. Now PTFE and other ePTFE gasketing in steel piping and equipment are facing a downfall. It is efficient & highly adapted to rough or irregular sealing surfaces. It is strong and compresses into an extremely tough gasket. Such a gasket creates a tight, long-lasting seal that stays taut for a really long time.

Generally, gaskets allow for "less-than-perfect" mating surfaces. On any part they are put, they work wonderfully and save a heap of money. Would you imagine replacing the gas chamber of your commercial plant just because of a small hole? NO! Instead, you’ll choose gasketing because it is a smarter option. Gaskets are produced by cutting from sheet materials & more recently non-asbestos gasket sheets are used. Earlier gaskets used for specific applications, such as high-pressure steam systems, contained asbestos. The use of asbestos is discontinued and totally banned at some places due to high health risks associated with it. From the time asbestos is banned and sheets without asbestos have come. The gasket industry has got a new definition. Kevlar is a type of fiber that is commonly used. It is an aramid fiber and is known for being around 3 to 9 times more durable than the old asbestos ones.

We at gasketmaterial.net offer you competitive pricing and minimal charges. Just provide us the critical dimensions of the compressed sheet gasket you require. We will give it to you in no time because our production run is fast. Our sheet gasketing technique is fast and durable. Open our website; check out our products and services. We discuss it with us in the case of any confusion.

Comments

Post a Comment