The use of graphite in gasket industry

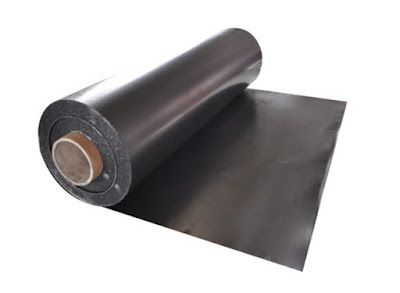

It will not be wrong to say that best thing that has happened to gasket industry in the recent years is the advent and penetration of graphite that is flexible and equipped with much potential. It is very much a reality that graphite in its numerous forms is being offered so that it can be used for the purpose of high temperature and medium pressure sealing applications. You can have it in various forms such as ribbon pack, sheet and braided.

The flexible graphite

There was time when flexible graphite was only reserved for high temperature applications, but now its use has extended to low temperature applications as well. One reason present behind this development is that price of graphite has now decreased because of this reason it is considered as an option, which is extremely cost effective. The material which goes into the making of graphite is capable of withstanding higher temperature ranges, chemical and pressures. The most prominent aspect related to the material is that it is free of all kinds of additives, bonders and the respirable fibers.

There are also the flake sheets of graphite which can stand in strong chemical environments and high pressure when compared with gasket material that is asbestos free. The presence of metal inside graphite permits it to operate at higher pressure as well.

In the past it was suggested that use of graphite should be avoided in oxidizing environments. However, now with the presence of certain passivation inhibitors oxidation as well as the corrosion resistance of graphite can be used with a lot more ease and confidence.

From the above discussion it is clear that use flexible graphite and viton sheet can bring great outcomes for you. If you want to have more information on this topic, then visit the our website.

Comments

Post a Comment