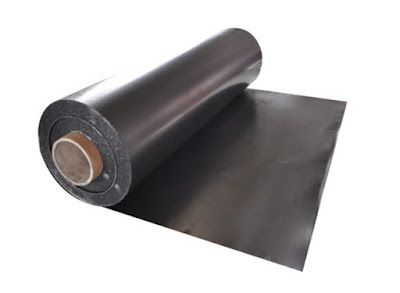

Graphite Gaskets a Blessing for Modern Industry

According

to experts the best thing that has happened to the sealing industry is none

other than the flexible graphite. As

well all know that in its various forms graphite these days is being used on a

wide scale for moderate and high-temperature sealing applications. You will

find it being offered in various forms such as ribbon pack, sheet and braided

etc. The utility value related to these kinds of products is very high because

of this reason you never face any kind of issue or disappointment at the time

of using them.

Why is graphite popular?

There was a

time when graphite was popularly used only for applications that involved high

temperature, but lately, it has also made its way in lower-temperature applications

because prices now are extremely affordable these days. Because of this reason

a graphite sheet now holds the status of cost effective high-temperature

material that can withstand high pressure as well as temperature. Graphite

gasket material is normally made using high-grade materials because of this

reason it exhibits great

sealing qualities and is capable of withstanding higher temperature

ranges, chemicals as well as pressure. The material is free of all kinds of

additives, binders, and fibers.

Best quality

The best

quality associated to graphite is that it can withstand extremes of temperature

which is a quality that should always be used in a material that is used on the

industrial level. There is just one point that should be kept in mind that

graphite can withstand temperature extremes, but it is not stable and can

break. The ideal solution in such circumstances is to use graphite gaskets that

have been reinforced by the stainless steel foils so that you can get

characteristic strength as well.

For more

information on non-asbestos

and flexible graphite gaskets, you can put a look at the http://gasketmaterial.net/non-asbestos-gaskets.php.

Comments

Post a Comment